MIT Valves

MIT BUTTERFLY VALVES CI DISC

The MIT Cast Iron (CI) Butterfly Valve with SG Iron Disc is a robust, reliable, and cost-effective solution designed for efficient flow regulation and shut-off applications in water, HVAC, fire-fighting, and industrial piping systems. Manufactured with a heavy-duty cast iron body and a spheroidal graphite (SG) iron disc, this valve ensures excellent strength, durability, and corrosion resistance. The wafer-type design allows for compact installation between flanges, making it ideal for space-constrained systems. With its smooth quarter-turn operation and precision-sealed construction, the MIT CI Butterfly Valve delivers long service life and low maintenance performance across a wide range of operating conditions.

- Body: High-grade Cast Iron construction for robust strength and durability.

- Disc: SG Iron disc with superior mechanical properties and resistance to wear and corrosion.

- Operation: Lever-operated with quarter-turn mechanism for easy and precise flow control.

- Design: Wafer type, compact and lightweight, suitable for horizontal or vertical installation.

- Seal: High-performance elastomer seat ensuring bubble-tight shut-off and leak-free operation.

- Applications: Water supply, HVAC systems, fire-fighting networks, chemical and industrial pipelines.

Technical Specifications:

- Size Range: 40p mm to 600 mm

- Pressure Rating: PN10 / PN16

- Body Material: Cast Iron (CI)

- Disc Material: SG Iron/SS DISC

- Seat: EPDM / NBR / Viton (as per application)

- End Connection: Wafer Type (compatible with ANSI, DIN, BS flanges)

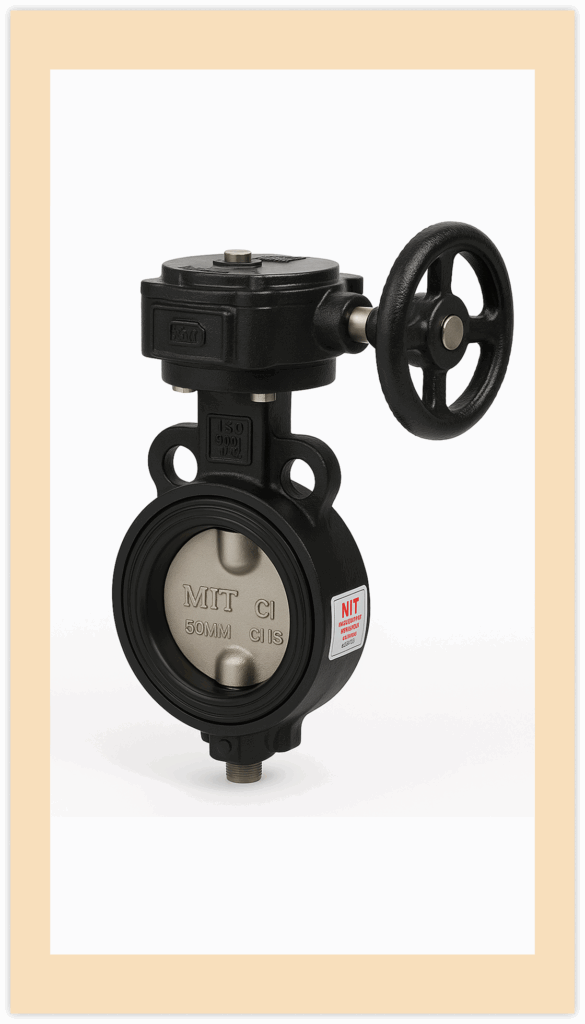

MIT Gear Type Butterfly Valves

MIT Gear Type Butterfly Valves are designed for efficient regulation and isolation of flow in pipelines. Manufactured with robust materials, these valves ensure durability, reliability, and long service life, making them ideal for industrial and commercial applications.

- Design: Lug/Wafer type with gear-operated handwheel for smooth and precise operation.

- Size Range: Typically available from 50mm (2”) up to 600mm (24”) and beyond.

- Body Material: Cast Iron (CI), Ductile Iron (DI), or other specified alloys.

- Disc Material: Stainless Steel, Cast Iron with epoxy coating, or as per client requirement.

- Seat/Lining: EPDM, Nitrile, Neoprene, or PTFE to suit a wide range of fluids and conditions.

- Operation: Heavy-duty gear box with handwheel, providing easy torque management for larger sizes.

- Pressure Rating: PN 10/PN 16.

- Temperature Range: Suitable for service conditions from -10°C to +120°C (depending on seat material).

- Standards: Conforms to international standards such as IS, AWWA, BS, or equivalent.

Applications:

- HVAC systems

- Water treatment plants

- Firefighting systems

- Irrigation and agricultural pipelines

- Industrial process lines (oil, gas, chemical, and power plants)

Advantages:

- Compact design and lightweight compared to gate and globe valves

- Excellent flow control with low pressure drop

- Easy installation between flanges

- Gear operation ensures precise throttling and reduced manual effort

- Long-lasting sealing performance

MIT Wafer Type Check Valve – Swing Type / Non-Return Valve

The MIT Wafer Type Check Valve is a compact, lightweight, and high-performance non-return valve designed to prevent backflow in pipeline systems. Its streamlined wafer design allows easy installation between flanges, significantly reducing weight and space requirements compared to conventional swing check valves. The valve operates automatically — the disc opens with forward flow and closes instantly when flow reverses, ensuring system integrity and preventing damage to pumps, compressors, and other downstream equipment.

Engineered with precision machining and robust materials, the MIT wafer check valve ensures reliable performance, low cracking pressure, and tight shut-off across a wide range of fluid applications including water, oil, gas, and chemical media. Its minimal maintenance design and durable construction make it an ideal choice for industrial, HVAC, water treatment, and fire-fighting systems.

- Automatic Operation: Opens with forward flow and closes immediately upon flow reversal to prevent backflow.

- Compact Wafer Design: Lightweight and space-saving, easy to install between standard flanges.

- High Durability: Constructed from premium-grade cast iron, carbon steel, or stainless steel for long service life.

- Leak-Proof Performance: Precision-machined disc and seat ensure tight shut-off and reliable sealing.

- Low Cracking Pressure: Reduces pressure loss and enhances system efficiency.

- Maintenance-Free: Simple design with minimal moving parts for low maintenance requirements.

Technical Specifications:

- Size Range: 40 mm to 600 mm

- Body Material: Cast Iron / Ductile Iron / Carbon Steel / Stainless Steel

- Disc Material: Stainless Steel / SG Iron

- Seat: Metal-to-Metal or Soft-Seated (NBR / EPDM / Viton)

- Pressure Rating: PN10 / PN16 / ANSI 150#

- End Connection: Wafer Type (fits between standard flanges)

Applications:

Water Supply, Fire-Fighting, HVAC, Industrial Process, Oil & Gas, Chemical Pipelines.

All Solutions

Your Industry. Our Expertise. One Trusted Solution.

Vision & Mission Statement

Where Leading Industries Rely — Relationships Forged Through Consistent Performance.

To be the benchmark of trust and performance in industrial supplies, where precision and reliability drive every connection we build. We don’t just support infrastructure — we strengthen its foundation.

To deliver top-tier pipe fittings and valves with unmatched speed, quality, and integrity. Our mission is simple — empower every project to perform better, last longer, and stand stronger.